CNC Control Upgrade Project - Toyota CNC Grinder

| Here is a live project installation you can follow. This Toyota CNC grinder is in the process of being upgraded with the professional level Centroid CNC control and Yaskawa Sigma5 servo products. |

Restore reliability - Increase production speed - Improve accuracy

Shorter setup times - Intuitive programming features |

|

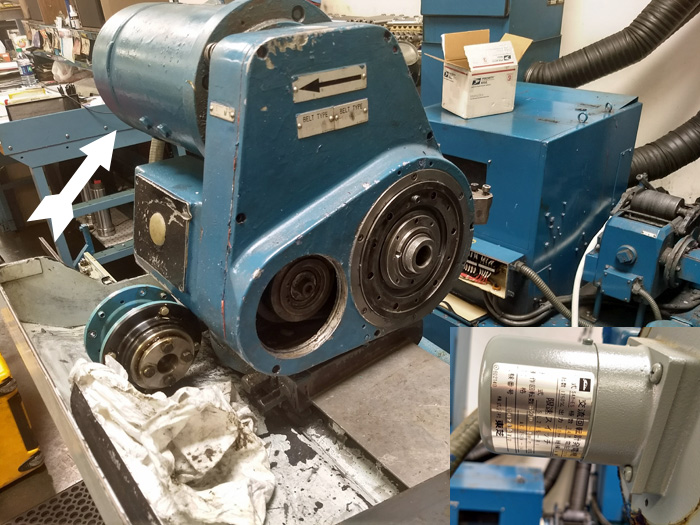

Starting this project April 30 2018. The CNC grinder pictured above has sat idle for 5 years due to a poorly executed CNC control upgrade. This customer was understandably hesitant to spend his money again, however, this Toyota is a very solid machine tool and the business is in needs of more production capability. After much vetting he chose Machines in Motion, Inc.

|

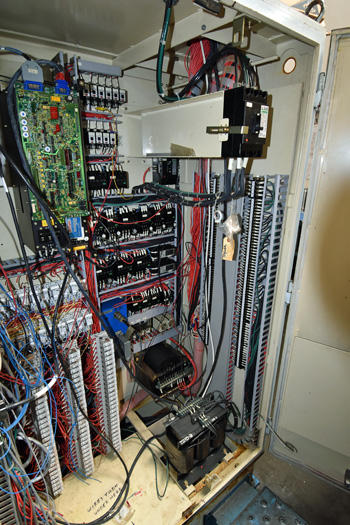

| The OEM CNC control had over 150 relays |

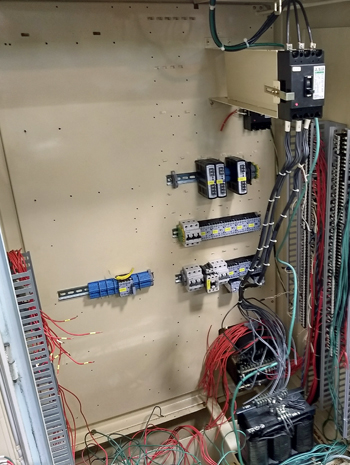

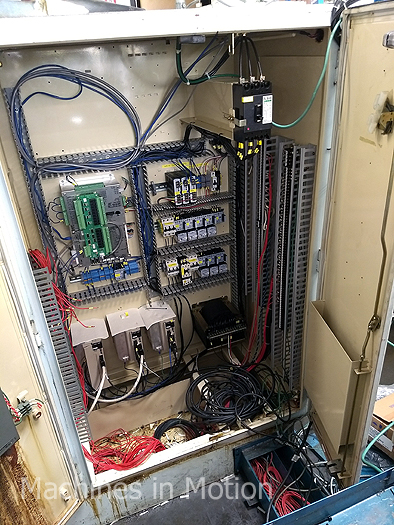

Poorly executed control upgrade. |

| End of the day and much of the old unreliable control hardware has been removed. |

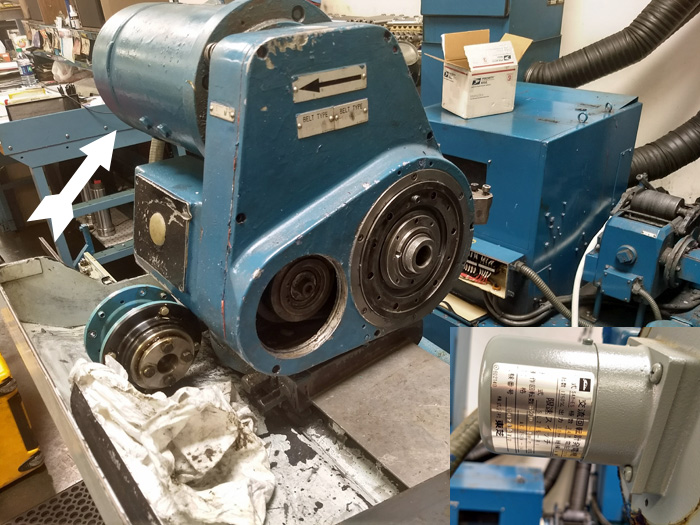

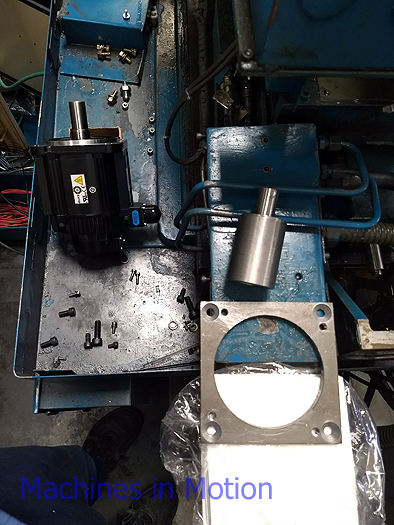

Day 2 presented us with a surprise.

| Turns out this motor was specially built for this application. No standard motor drive will power this hybrid DC motor. It will need to be replaced. |

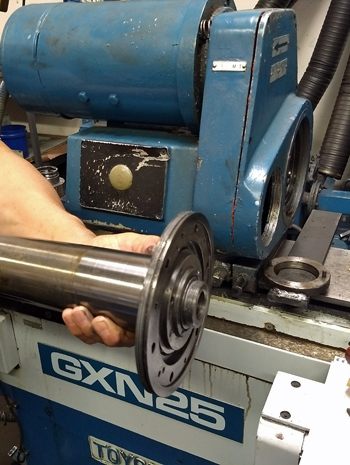

| Begin day 3 on-site. After others had tried I was finally able to remove the drive shaft. |

Further inspection found this was in needed repairs. |

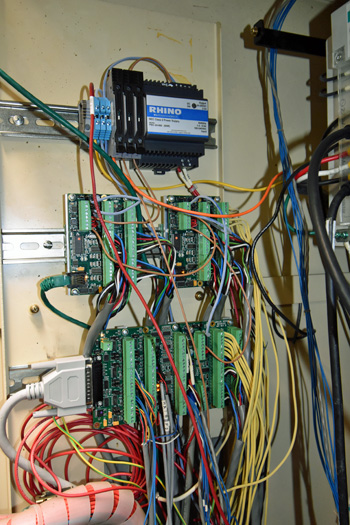

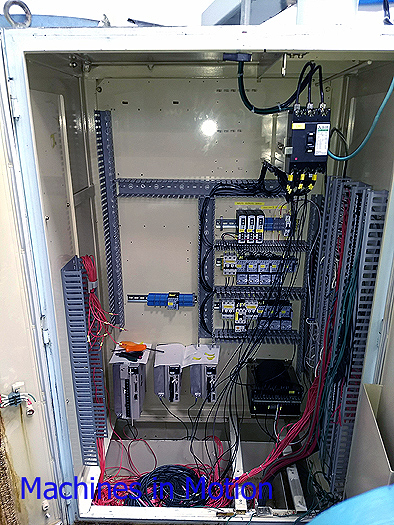

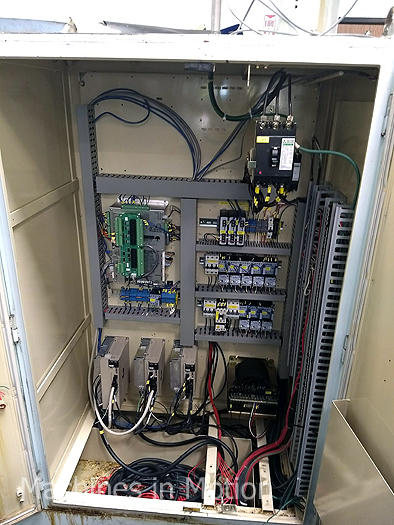

| Begin installation of new electrical hardware |

What a good working environment looks like. |

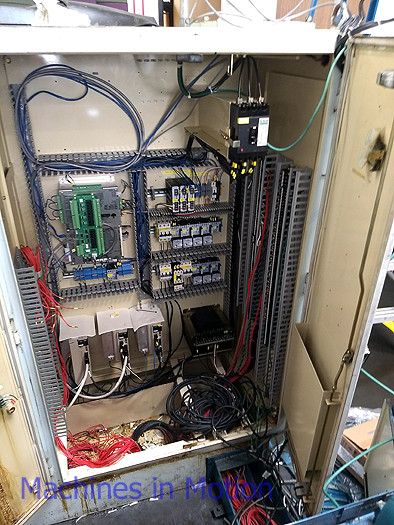

| Next day on-site mounting wire track plus more wiring. |

Day 5 on-site. Confirm the new motor mounts are correct. |

| CNC control hardware has arrived. More wiring and mounting. |

I like to clean up the work area befor calling it a day. |

| 6th Day on-site got a lot of wiring completed. |

7th day on site. Ran motor cables through the casting. |

| I was able to complete the CNC control wiring today. |

Mounted the new Centroid console onto the OEM arm. |

This Grinding house wanted special conversational part programming.

Machines in Motion was able to provide this.

Now they can fill in the values found on the part print then press cycle start.

Machines in Motion's experience in CNC control replacement can benefit your business.

Call us (714) 528-7061 |

| Put us to work for you |

|

|

Centroid CNC Retrofit by Machines in Motion, Inc.

Contact us directly or Email us at Centroid.controls@gmail.com

(c) Copyright 2019 Machines in Motion