Optional features for your Centroid CNC controller

|

Centroid Controllers can Digitize solid models

Centroid Digitizing Cycles are commonly used to copy 2D or 3D shapes and contours of an existing part. Commonly used for reverse engineering the Centroid digitizing data can be exported to a cad cam system for further geometry manipulation or run as a G code program immediately.

Probing for fast & accurate part setup

Centroid Probing cycles are used to make part setup faster and more accurate with less work. Easily find centers or bores, corner of parts or vise in seconds with fantastic accuracy. If your shop is always tearing down and setting for different jobs Centroid Probing pays for itself in a very short time. Centroid's probing package includes the Centroid DP-4 probe, the Centroid menu driven probing cycles and Coordinate System Rotation. The Centroid menu driven probing cycles are as follows. Bore, Boss, Inside Corner, Outside Corner, Edge, Slot, Web, Single Axis.

|

Automatic Tool Length measurement

|

Make multiple tools setting simple

Set up your tools in a quarter of the time it would normally take! If you often machine short-run parts and are always setting up and tearing down for a new job, the TT-1 Auto tool set will save you tons of time while more accurately setting your tool height offsets. With the TT-1 you

can create more parts per hour since the tool setup is so much faster. You'll even save time when you have to replace a dull tool with a new one in the middle of a job. The TT-1 is completely automatic. Press "measure" and the tool will automatically touch off the TT-1 and set the tool height offset

in the tool library. Requires conductive tooling and spindle.

|

Rigid Tapping

|

Rigid tapping speeds threading of parts

CENTROID's advanced rigid tapping cycles are simple to program through G-code, Cad/Cam or Intercon. In Intercon, you get an extra cycle called Deep Hole Rigid Tapping, (see a video here) Deep Hole tapping taps a hole much in

the same way as you would by hand. It backs out of the thread to clear the chips and then matches right back up with the new threads and continues the tapping. Another advantage of deep hole tapping is that it allows you to tap a much larger

hole than the HP of your machine would normally allow.

|

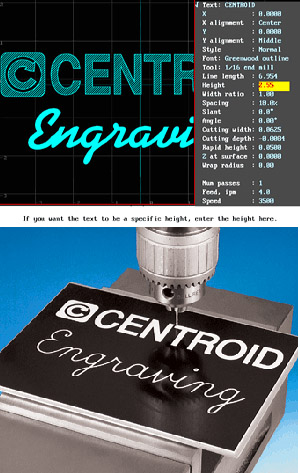

Conversational Engraving Software

|

Add Text or Logo Engravings on your parts

Screen shot of the Simple to learn Conversational Engraving Software. A library of different fonts is included. Select from many popular logos or add your own logo to the library.

Create raised letters, standard below surface engraving, and custom Logos.

No special machine needed.

No CadCam experience required.

On-Screen control over placement, rotation, and scaling.

You can even force text to fit a specific height or width.

|

Traditional Wired MPG Handwheel

|

Visual and Tactale comfort of an axis handwheel

This is considered a personal preference item so we make it your choice. Some operators are comfortable reaching for the push buttons when jogging. Others like the feel of a rotating wheel. It's a low cost addition to your new CNC control.

|

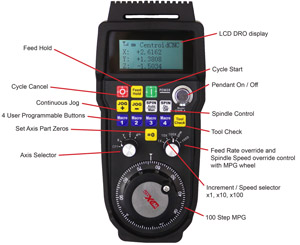

Deluxe Wireless Hand Wheel

|

Visual and Tactale feedback plus so much more.

The wireless age has arrived. Due to safety concerns the CNC industry has held back until the bugs were worked out. Today we offer a wireless hand wheel with LCD position display plus the most popular button and rotary controls found on our professional console.

Click on the image for an enlarged view. Not shown on our current options price list. $215 + $139.

|

4th Axis Rotary Table

|

Make multiple tools setting simple

Sometimes parts require rotary positioning before machining. Sometimes parts require rotating WHILE machining. And there is money to be made by engraving on the curve of a round part.

However you use it this family of rotary tables will place your shop skills in a higher category. Add one of our programmable rotary axis for far less than the competition.

|

Centroid CNC Retrofit by Machines in Motion, Inc.

Contact us directly or Email us at Centroid.controls@gmail.com

(c) Copyright 2019 Machines in Motion

| | | | | | | |